Your Complete Guide to Windscreen Repair Questions: Expert Answers from Wollongong AutoGlass

Australian drivers frequently have questions about windscreen repair processes, costs, and timing that can impact their decisions about addressing automotive glass damage. Understanding the most common concerns helps drivers make informed choices about windscreen maintenance while ensuring safety and legal compliance throughout the repair process.

Insurance Coverage and Claim Procedures

Insurance coverage for windscreen repairs and replacements varies significantly between policies and providers, making it essential for drivers to understand their specific coverage details before damage occurs. Most comprehensive vehicle insurance policies include windscreen coverage, but excess amounts, preferred repairer requirements, and coverage limitations can affect the actual costs and procedures involved in claiming for windscreen work. Understanding these policy details helps drivers or fleet managers plan appropriate responses to windscreen damage while maximising insurance benefits.

Excess waiver programmes offered by many insurers recognise that prompt windscreen repairs prevent more expensive damage while maintaining vehicle safety standards. These programmes typically waive standard excess amounts for windscreen repairs under specific conditions, such as using approved repairers or addressing damage promptly after occurrence. However, complete windscreen replacements may still attract standard excess amounts depending on policy terms and damage circumstances.

Claim procedures require prompt notification to insurers and may involve inspection processes, approved repairer requirements, or documentation needs that affect repair timing and service provider selection. Understanding these procedures before damage occurs helps ensure smooth claim processing while avoiding potential complications that could delay repairs or increase out-of-pocket costs. Some insurers also offer direct billing arrangements with approved repairers that eliminate upfront payment requirements for covered work.

Insurance Claim Essentials

Key factors affecting windscreen insurance claims:

- Coverage verification: Confirming windscreen damage inclusion in your specific policy.

- Excess amounts: Understanding cost obligations for repairs versus complete replacements.

- Preferred networks: Benefits and limitations of using insurer-approved service providers.

- Reporting timeframes: Prompt notification requirements affecting claim validity.

- Documentation needs: Photos, police reports, or inspection requirements for claim processing.

- Quality guarantees: Warranty coverage for completed repairs and replacement work.

Repair vs Replacement Decision Factors

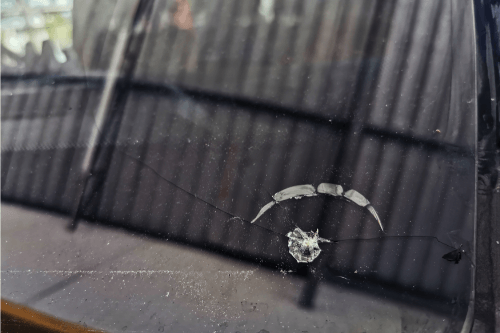

The decision between windscreen repair and complete replacement depends on multiple factors, including damage size, location, type, and age, that professional technicians evaluate using industry standards and safety criteria. Small chips and cracks under specific size thresholds can often be repaired effectively, restoring structural integrity and optical clarity while avoiding the expense and inconvenience of complete windscreen replacement. However, damage exceeding size limits or located in critical vision areas typically requires replacement to ensure safety and legal compliance.

Damage location plays a crucial role in repair versus replacement decisions, with damage in the driver's primary vision area often requiring replacement regardless of size to maintain optimal visibility and safety standards. Edge damage or cracks extending to the windscreen perimeters may also necessitate replacement due to structural integrity concerns, even when damage appears minor. Professional assessment helps determine appropriate treatment approaches based on safety standards rather than cost considerations alone.

Age and propagation characteristics of windscreen damage influence treatment decisions, as older damage that has spread or shows signs of continued growth typically requires replacement to prevent sudden failure. Fresh damage often responds well to repair procedures, but damage that has been present for extended periods may have developed stress patterns or contamination that compromise repair effectiveness and longevity.

Repair Suitability Criteria

Damage characteristics determining repair feasibility:

- Size limitations: Chips under 20mm and cracks under 150mm are typically repairable

- Location restrictions: Damage outside the driver's primary vision zone is preferred for repairs

- Damage age: Fresh damage is generally more suitable for successful repair outcomes

- Contamination levels: Clean damage responds better to repair procedures than contaminated damage

- Structural integrity: Damage not affecting windscreen mounting or edge stability

- Multiple damage: The Combined effect of several chips or cracks influences treatment decisions.

Quality Standards and Certification Requirements

Australian automotive glass installation and repair services must comply with strict quality standards that ensure the safety, durability, and performance of completed work. Australian Standard AS/NZS 2080 governs automotive glass installation procedures, specifying requirements for materials, installation techniques, and quality control measures that protect vehicle occupants whilst ensuring optimal windscreen performance. Professional services adhering to these standards provide consistent quality results backed by comprehensive warranties and industry certification.

Technician certification requirements ensure that automotive glass work is performed by qualified professionals with appropriate training and ongoing education in current techniques and safety procedures. Certified technicians understand proper installation procedures, adhesive requirements, and curing times necessary for safe vehicle operation whilst maintaining compliance with manufacturer specifications and insurance requirements.

Material quality standards specify the types of glass, adhesives, and components that meet Australian safety requirements for automotive applications. Original Equipment Manufacturer (OEM) glass provides optimal fit and performance characteristics, whilst aftermarket alternatives must meet equivalent safety and quality standards to ensure proper function and legal compliance. Understanding these material standards helps customers make informed decisions about replacement options and quality levels.

Quality Assurance Elements

Professional services maintain these standards:

- Technician certification: Industry-recognised training and competency verification.

- Material compliance: Approved glass and adhesive products meeting safety standards.

- Installation procedures: Standardised techniques ensuring consistent quality results.

- Quality control: Systematic inspection and testing procedures for completed work.

- Warranty coverage: Comprehensive guarantees protecting customers against premature failure.

- Safety protocols: Procedures protecting workers, customers, and property during service.

Mobile Service Convenience and Limitations

Mobile windscreen services provide exceptional convenience for busy customers by bringing professional repair and replacement capabilities directly to homes, workplaces, or other convenient locations throughout the service area. Modern mobile units are equipped with the same professional tools, materials, and equipment used in workshop facilities, enabling high-quality work completion in various environmental conditions. This convenience eliminates travel time and vehicle unavailability whilst providing professional results that meet all quality and safety standards.

Environmental considerations affect mobile service availability and quality, with weather conditions, location accessibility, and workspace requirements influencing service feasibility for specific jobs. Wind, rain, temperature extremes, or inadequate workspace may require rescheduling mobile services or completing work at workshop facilities to ensure optimal results. Understanding these limitations helps set appropriate expectations whilst planning service timing around weather and location factors.

Complex installations involving advanced vehicle technologies, specialised glass types, or challenging mounting systems may require workshop facilities with specific equipment and controlled environments for optimal results. Mobile services excel for standard repairs and straightforward replacements, but may recommend workshop completion for technically demanding installations that benefit from specialised facilities and equipment.

Mobile Service Considerations

Evaluate these factors for mobile service suitability:

- Weather conditions: Temperature, wind, and precipitation affect work quality

- Location accessibility: Adequate workspace and vehicle access for professional completion

- Job complexity: Technical requirements that may benefit from workshop facilities

- Time constraints: Scheduling flexibility for curing times and quality control

- Equipment needs: Specialised tool requirements for specific vehicle types

- Safety factors: Environmental hazards or restrictions affecting mobile work completion.

Windscreen Technology and Advanced Features

Modern windscreens incorporate sophisticated technologies that significantly affect repair and replacement procedures, costs, and calibration requirements following installation. Advanced Driver Assistance Systems (ADAS) rely on windscreen-mounted cameras, sensors, and other components that require precise positioning and calibration to function correctly after windscreen work. Understanding these technology dependencies helps customers appreciate the complexity and value of professional installation services whilst planning appropriate budgets for complete system restoration.

Heated windscreen and defrosting systems require specialised knowledge and procedures to maintain electrical continuity and proper function following repair or replacement work. These systems involve complex wiring, heating elements, and control systems that must be properly connected and tested to ensure continued operation and safety. Professional technicians understand these requirements and can restore full functionality whilst maintaining manufacturer warranties and safety standards.

Rain sensors, automatic wipers, and heads-up display systems depend on specific windscreen properties and positioning that must be maintained during replacement procedures. Even minor variations in windscreen specifications or mounting positions can affect these systems' operation, making professional installation and calibration essential for maintaining full vehicle functionality and convenience features.

Technology Integration Challenges

Modern windscreen technologies require these considerations:

ADAS calibration: Precise sensor positioning and system recalibration following replacement.

Heating element continuity: Electrical system testing and connection verification.

Sensor compatibility: Rain sensors and automatic systems require specific windscreen properties.

Display integration: Heads-up displays and projection systems need exact positioning.

Coating preservation: UV filters and other treatments affecting system operation.

Warranty compliance: Maintaining manufacturer coverage through proper installation procedures.

Repair Process Timeline and Expectations

Windscreen repair procedures typically require 30-60 minutes for completion, depending on damage complexity, environmental conditions, and curing requirements for repair materials. Professional repairs involve cleaning damaged areas, injecting specialised resins, and curing processes that restore structural integrity whilst minimising visible repair evidence. Understanding typical timeframes helps customers plan schedules whilst setting realistic expectations for repair completion and vehicle availability.

Curing time requirements following repairs may restrict immediate vehicle use, particularly for adhesive-based repairs that require specific time periods to achieve full strength. Environmental conditions, including temperature and humidity, affect curing times, with optimal conditions enabling faster completion, whilst challenging conditions may extend required curing periods. Professional technicians provide specific guidance about post-repair vehicle use based on actual conditions and repair materials used.

Quality control procedures following repair completion include visual inspection, pressure testing, and structural verification that ensure repairs meet safety and performance standards before returning vehicles to service. These final checks provide confidence in repair quality whilst identifying any issues that require additional attention before customer handover.

Typical Repair Timeline

Standard windscreen repair procedures follow this sequence:

- Damage assessment: Initial evaluation determining repair feasibility and approach (5-10 minutes)

- Preparation: Cleaning and setup procedures, preparing damaged area for treatment (10-15 minutes)

- Repair injection: Resin application and pressure procedures restoring structural integrity (15-20 minutes)

- Curing process: Material hardening and bonding, achieving full strength (15-30 minutes)

- Quality control: Final inspection and testing, ensuring repair effectiveness (5-10 minutes)

- Customer handover: Instructions and warranty information for completed work (5 minutes).

Cost Factors and Pricing Transparency

Windscreen repair and replacement costs vary based on multiple factors, including vehicle type, glass specifications, technology features, and service location, which affect material requirements and labour complexity. Understanding these cost factors helps customers evaluate quotes effectively while making informed decisions about repair timing and service provider selection. Transparent pricing practices provide detailed breakdowns that explain cost components and help customers understand value for their investment.

Vehicle specifications significantly impact replacement costs, with luxury vehicles, imported cars, and technology-equipped windscreens typically requiring higher-cost materials and more complex installation procedures. Additionally, vehicles with unique glass shapes, acoustic properties, or integrated technologies may require specialised sourcing that affects availability and pricing compared to standard replacement glass for common vehicle models.

Service location factors can affect costs through travel charges for mobile services, accessibility challenges, or environmental conditions requiring special procedures. However, mobile service convenience often justifies modest additional costs through time savings and reduced inconvenience compared to workshop-based services that require customer travel and vehicle drop-off arrangements.

Pricing Influence Factors

These elements affect windscreen service costs:

- Vehicle specifications: Make, model, and year determine glass requirements and complexity.

- Technology features: ADAS, heating elements, and sensors affecting installation procedures.

- Glass type selection: OEM versus aftermarket options with different cost and quality characteristics.

- Service location: Mobile versus workshop completion affecting convenience and pricing.

- Urgency requirements: Emergency services typically attract premium pricing.

- Warranty levels: Extended warranty coverage affects overall service value and pricing.

Warranty Coverage and Service Guarantees

Comprehensive warranty coverage provides essential protection against premature failure whilst demonstrating service provider confidence in their workmanship and material quality. Quality windscreen services typically offer warranties covering both materials and labour for specified periods, ensuring customers receive lasting value whilst providing recourse if problems develop following completed work. Understanding warranty terms and coverage limitations helps evaluate service providers whilst ensuring appropriate protection for windscreen investments.

Workmanship warranties cover installation quality and procedures, protecting customers against problems resulting from improper techniques or inadequate preparation during repair or replacement procedures. These warranties typically address issues such as adhesive failure, improper mounting, or installation defects that could compromise windscreen performance or safety. Professional services stand behind their work through comprehensive workmanship guarantees that provide peace of mind and quality assurance.

Material warranties cover glass quality and manufacturing defects that could affect windscreen performance or durability following installation. Quality glass suppliers provide warranties against defects, whilst professional installers often extend additional coverage for complete customer protection. Understanding both material and workmanship warranty coverage helps ensure comprehensive protection while evaluating total service value and long-term cost considerations.

Warranty Protection Elements

Comprehensive warranties typically include:

- Workmanship guarantees: Coverage against installation defects and procedural problems.

- Material warranties: Protection against glass manufacturing defects and premature failure.

- Adhesive coverage: Guarantees against bonding failures and mounting problems.

- Leak protection: Coverage against water infiltration and weather seal failures.

- Stress crack coverage: Protection against installation-related stress damage.

- Service guarantees: Commitment to address any warranty issues promptly and professionally.

Emergency Services and After-Hours Support

Emergency windscreen services provide critical support when sudden damage creates immediate safety hazards or legal compliance issues that cannot wait for standard business hours. Complete windscreen failure, significant vision obstruction, or damage occurring before important travel can necessitate emergency repair or replacement services that restore vehicle safety and usability quickly. Understanding emergency service availability and procedures helps drivers respond appropriately to urgent windscreen problems.

After-hours support recognises that windscreen damage often occurs outside normal business hours through accidents, storms, or vandalism that require prompt attention for safety and security reasons. Professional services offering emergency response provide peace of mind whilst ensuring that urgent windscreen problems receive appropriate attention regardless of timing. However, emergency services typically attract premium pricing due to the specialised scheduling and resource requirements involved.

Temporary safety measures may be recommended when immediate professional service isn't available, helping drivers maintain basic safety whilst arranging appropriate repairs. These interim solutions focus on preventing further damage and maintaining minimal safety standards until professional work can be completed, though temporary measures should never be considered permanent solutions to windscreen damage.

Emergency Service Scenarios

These situations typically require urgent windscreen attention:

- Complete windscreen failure: Total glass loss requiring immediate replacement for safety.

- Severe vision obstruction: Damage preventing safe vehicle operation.

- Security compromises: Broken glass creates vehicle security vulnerabilities.

- Weather exposure: Damage allowing water infiltration during storms.

- Legal compliance urgency: Immediate repair needs for registration or inspection requirements.

- Travel necessities: Essential vehicle use requiring urgent windscreen restoration.

Conclusion

Understanding windscreen repair and replacement processes helps Australian drivers make informed decisions about automotive glass maintenance while ensuring safety, legal compliance, and optimal value for their investment. From insurance considerations and repair versus replacement decisions to emergency services and warranty protection, comprehensive knowledge enables confident navigation of windscreen issues when they arise.

Professional windscreen services provide expertise, quality materials, and comprehensive warranties that ensure optimal outcomes while supporting long-term vehicle safety and performance. By addressing windscreen damage promptly using qualified services, drivers can maintain clear visibility, structural integrity, and legal compliance while minimising costs and inconvenience associated with automotive glass problems.

About Wollongong AutoGlass

Wollongong AutoGlass provides professional windscreen repair and replacement services across Australia, offering comprehensive automotive glass solutions backed by industry expertise and quality guarantees. Our certified technicians deliver reliable repairs and replacements that ensure optimal safety, performance, and legal compliance for all vehicle types.